Delivery Cycle Time

A Measure of Internal

Business Process Performance:

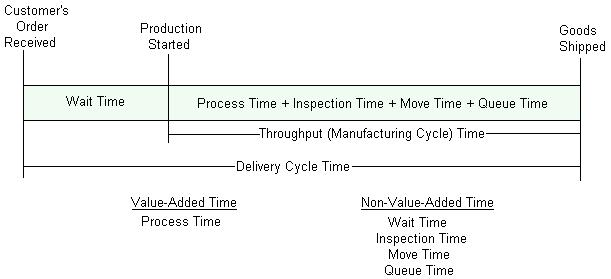

Delivery cycle time is an important measure

of internal business process performance.

Performance measures are found on the

balanced scorecards of the companies. Examples of the some

performance measures can be found on

characteristics of balanced scorecard page. Most

of the performance measures are self explanatory.

However, three are not - delivery cycle time,

throughput time, and manufacturing cycle efficiency

(MCE). On this page, deliver cycle time is defined,

explained and calculated.

Definition and Explanation:

The

amount of time from when an order is received from a

customer to when the completed order is shipped is

called delivery cycle time. This time is

clearly a key concern to many customers, who would

like the delivery cycle time to be as short as

possible. Cutting the delivery cycle time may give a

company a key competitive advantage - and may be

necessary for survival. Consequently, many companies

would include this performance measure on their

balanced scorecard.

Delivery Cycle Time and Throughput (Manufacturing

Cycle) Time

Formula:

|

Delivery Cycle Time = Wait time +

Throughput time |

Example

Calculation of

Delivery Cycle Time:

Novex Company keeps

careful track of the time relating to orders and

their production. During the most recent quarter,

the following average times were recorded for each

unit or order:

| Wait

time |

17.0 |

|

Inspection time |

0.4 |

|

Process time |

2.0 |

| Move

time |

0.6 |

| Queue

time |

5.0 |

Goods are shipped as soon as production is

completed.

Required:

Calculate the

delivery cycle time.

Solution:

Delivery Cycle Efficiency = Wait time + Through

=

17.0 days + 8.0 days*

=

25.0 days

*Throughput

time = Process time + Inspection time + move time +

Queue time

2.0

days + 0.4 days + 0.6 days + 5.0 days

= 8.0

days

Relevant Articles:

|