Manufacturing Cycle Efficiency

(MCE)

A Measure of Internal

Business Process Performance:

Manufacturing cycle efficiency (MCE)

is an important measure of internal

business process performance.

Performance measures are found on the

balanced scorecards of the companies. Examples of the some

performance measures can be found on

characteristics of balanced scorecard page. Most

of the performance measures are self explanatory.

However, three are not -

delivery cycle time,

throughput time, and manufacturing cycle efficiency

(MCE). On this page, manufacturing cycle efficiency

(MCE) is defined,

explained and calculated.

Definition and Explanation:

value

added time as a percentage of

throughput time

is called manufacturing cycle efficiency.

Through concerted efforts to eliminate the non-value

added activities such as inspecting, moving, and

queuing, some companies have reduced their

throughput time

to only a fraction of previous levels. In turn, this

has helped to reduce the delivery cycle time from

months to only weeks or hours. Throughput time,

which is considered to be a key measure in delivery

performance, can be put into better perspective by

computing the manufacturing cycle efficiency (MCE).

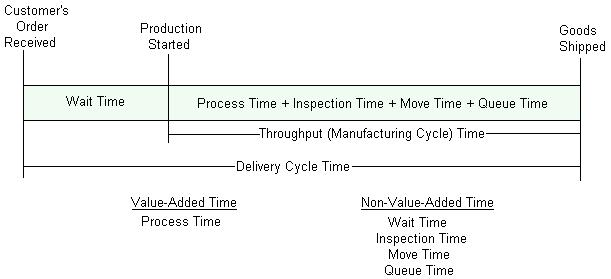

Exhibit 1-1:

Delivery Cycle Time and Throughput (Manufacturing

Cycle) Time

Formula:

|

MCE = Value-added time / Throughput time |

If the MCE is less

than 1, then non-value added time is present in the

production process. An MCE of 0.5, for example,

would mean that half of the total production time

consisted of inspection, moving, and similar

non-value-added activities. In many manufacturing

companies, it is less than 0.1 (10%), which means

that 90% of the time a unit is in process is spent

on activities that do not add value to the product.

By monitoring the MCE, companies are able to reduce

non-value-added activities and thus get products

into the hands of customers more quickly and at a

lower cost.

Example

Calculation of

Manufacturing Cycle Efficiency:

Novex Company keeps

careful track of the time relating to orders and

their production. During the most recent quarter,

the following average times were recorded for each

unit or order:

| Wait

time |

17.0 |

|

Inspection time |

0.4 |

|

Process time |

2.0 |

| Move

time |

0.6 |

| Queue

time |

5.0 |

Goods are shipped as soon as production is

completed.

Required:

Calculate manufacturing cycle

efficiency.

Solution:

MCE =

Value-added time

/ Throughput time

MCE = 2.0

days*

/ 8.0 days**

= 0.25

*Only

process time (2.0 days) represents

value-added time

**Throughput

time = Process time + Inspection time + move time +

Queue time

= 2.0

days + 0.4 days + 0.6 days + 5.0 days

= 8.0

days

Real Business

Example:

Expediting Loan Applications:

Banks ordinarily require three to four weeks

to approve an application for a mortgage

loan on a house. The application form

includes the individual's employment

history, income, and financial assets and

liabilities. Personnel at the ban check

credit references and review the entire

application before granting the loan. A

manager at one bank wondered why this this

process takes so long and asked employees to

keep track of how much time they actually

worked on processing an application. He

discovered that processing an application

took on average 26 days, but only about 15

minutes of this time was actual work. All of

the rest of the time the application was

waiting to someone's in-basket. The

manufacturing cycle efficiency was therefore

only 0.0004 [15 minutes / (26 days × 24

hours per day × 60 minutes per hour)]. By

redesigning and automating the process, the

cycle time was cut down to 15 minutes and

the MCE rose up to 1.0. Loan applicants can

now have a cup of coffee while waiting for

approval.

Source: Kaplan and Norton, Translating

Strategy into Action: The Balance Scorecard,

1996, pp. 118-119 |

Relevant Articles:

|